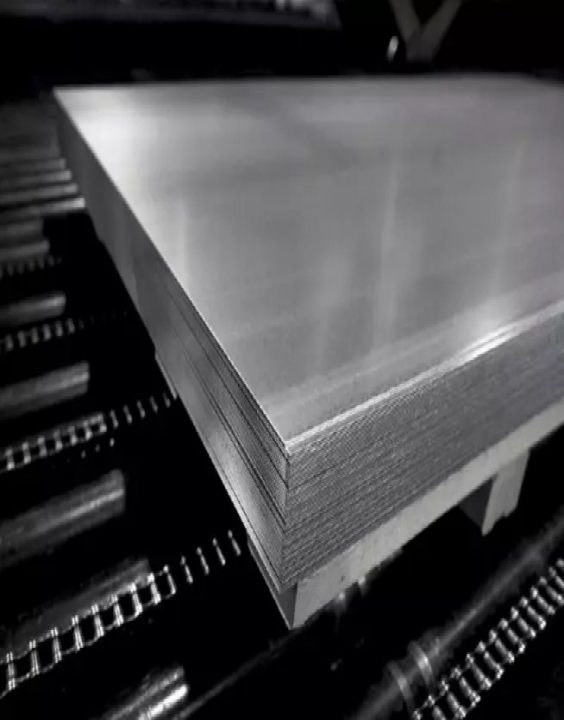

Sheet metal storage tower

Long metal sheets are unfortunately among the most difficult and valuable goods to handle. It is these that logistics and warehouse owners used to have the most conundrums with. If you are a manufacturer of these types of metal parts, you are probably looking for the optimal solution to store them efficiently in your warehouse. Thanks to automated racking, which has been dominating modern warehouses for some time now, we can provide the optimum solution for ergonomic room layout. In addition, automation ensures smooth workflows on the production floor. We would like to point out at the outset that in the case of sheet material storage, finding a solution that makes maximum use of the available storage space and reduces operating costs is of key importance for increasing company productivity. Fortunately, Logitower’s turnkey solutions can help. Sheet metal storage in the metal industry is a careful process. However, if you follow a few rules and adapt your storage system to the specific commodity of sheet metal, you will certainly not have any problems running such a business.

How to store heavy and long goods such as sheet metal?

To minimize the loss of goods and to ensure on-time delivery, it is also necessary to secure the stored items properly. With the LogiTower automatic storage system you can divide the shelves into smaller zones, which protects selected types of long items from contact with other metals and makes it easier to access individual items. With the help of LogiTower, you can really save a lot of time. Each shelf of the sheet metal storage tower can support a weight of up to 8,000 kg and a length of up to 12 meters, allowing for the efficient storage of items such as sheet metal, plates, etc. Our individually tailored LogiTower single or double-tower systems adequately protect sensitive components and reduce production losses, which is particularly important for sheet metal storage. In addition, the Logitower systems make it possible to save space and access time.

Easy and quick access to selected goods

Sheet material storage requires easy access for loading and unloading goods. LogiTower provides the possibility of orderly storage of sheet metal and other non-standard items and also works with in-line machines such as laser and waterjet cutting. Automation of the process of loading and unloading of long goods contributes to reducing the time of these operations and therefore the profit for the company. Such a demanding material as metal sheets is extremely bulky, heavy, somewhat flexible and therefore prone to damage. A misplaced investment can result in large losses of material, production time, claim costs, etc. Often, the sheet has sharp edges and corners, requiring exceptional storage. For this purpose, automated solutions from the LogiTower portfolio – single, double or multi-tower storage system and LogiComb – will work perfectly. It is worth equipping the warehouse with a WMS system. Employees then have access to the history of warehouse operations, goods retrieved and information on current stock levels.